Choosing the Right Welding Service: A Comprehensive Guide

Welding is a skill that merges science with art, and when it comes to choosing a welding service for your project, the stakes are high. The right welding service can ensure the structural integrity and longevity of the final product. This guide aims to steer you in the right direction, ensuring you team up with welders who are up to the task.

1. Expertise and Experience

Welding is an age-old craft, yet every project has nuances that require a modern understanding and skilled hands-on deck.

- Long-Standing Reputation: Seek a welding service with a solid reputation. It's the happy customers and successful projects in their portfolio that speak volumes about their capability.

- Certified Skillset: Certification in the welding industry is a clear indicator of skill. It assures you that the welders have been through rigorous training and assessment, ensuring they’re cut out for the job.

2. Equipment and Technology

Welding has seen technological advancements over the years. The equipment and technology a service employs can significantly affect the quality and efficiency of the work.

- Modern Machinery: Look for a service that has kept pace with modern welding equipment. It’s about achieving precise, efficient, and safer operations.

- Embracing the New: The welding realm is evolving with new technologies like laser welding making a mark. A service that’s open to adopting new technologies can offer you superior quality work.

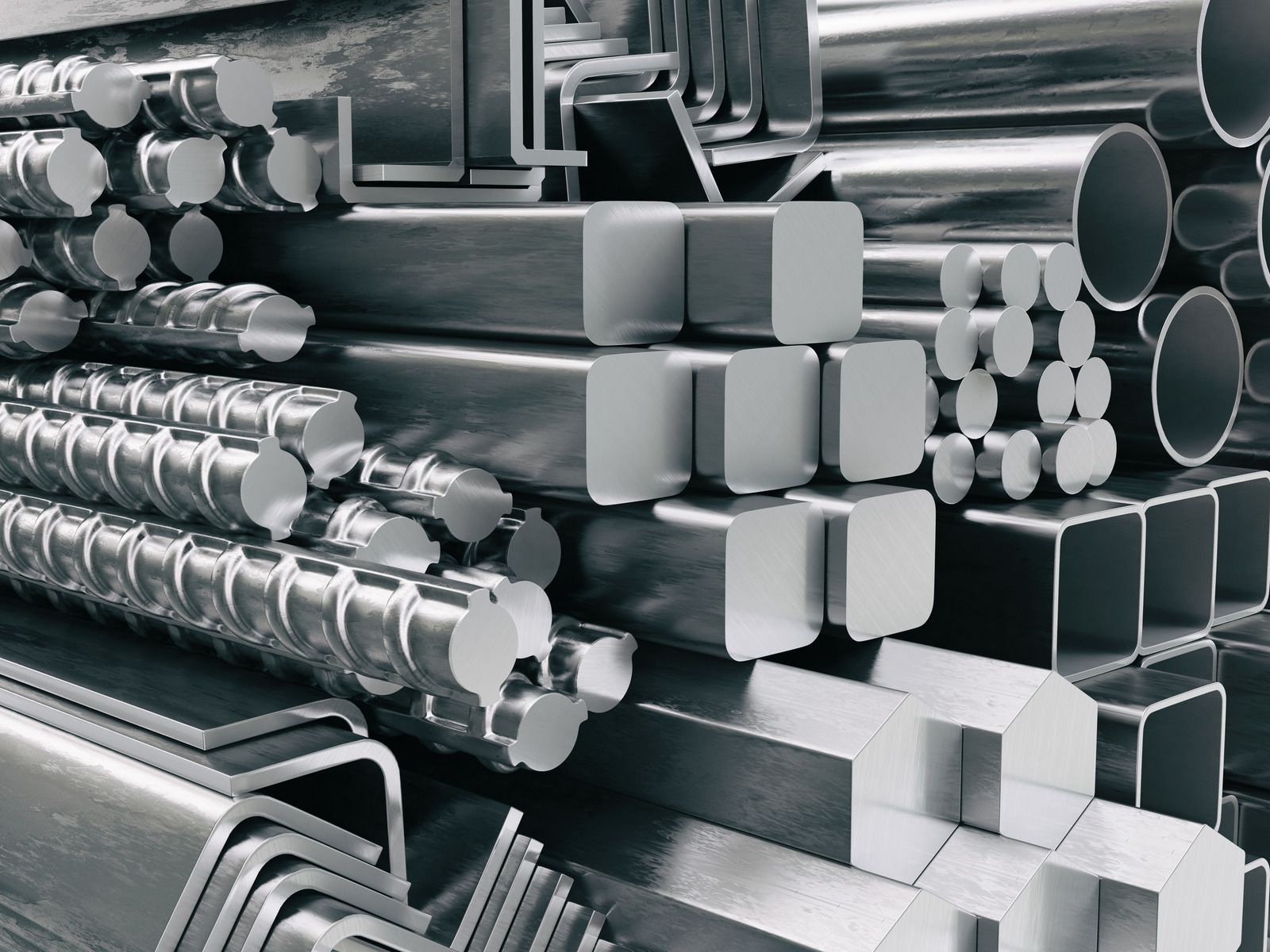

3. Material Specialization

Not all materials are welded the same way; each has its own set of welding techniques. Hence, material specialization is something you can’t afford to overlook.

- Material Wisdom: Ensure the service you choose has a good grasp over the materials involved in your project. They should know the ins and outs of handling different metals to ensure strong and durable welds.

- Compatible Handling: Be it aluminum, stainless steel, or any other metal, the welding service should be adept at working with the material your project demands.

4. Pricing and Project Evaluation

Clear communication about pricing and project expectations is the cornerstone of a successful collaboration.

- Transparent Quotations: A detailed quote that breaks down the cost lets you know where your money is going. It also helps in avoiding any unexpected costs down the line.

- Thorough Assessment: A service willing to evaluate the project thoroughly before jumping in is a keeper. It reflects their commitment to understanding the scope and requirements of the work.

5. Customer Service and Communication

Your journey with a welding service extends beyond just the technical aspect of welding. Good communication and customer service play a vital role in a hassle-free experience.

- Open Channels: Opt for a service that’s responsive, clear in communication, and willing to keep you in the loop through every phase of the project.

- Support Beyond Completion: Post-project support is crucial. There could be concerns or issues that arise after the completion, and knowing that the service is there to assist you is reassuring.

So, choosing the right welding service is a task but well worth the effort. It’s about entrusting someone with a significant part of your project, and you want to make sure they are well-equipped, skilled, and reliable. By paying attention to their expertise, equipment, material handling, pricing transparency, and customer service, you pave the way for a successful welding project and a pleasant experience.