Channel Rolling Service

Importance of Channel Rolling in Steel Fabrication

Channel rolling is an important part of steel fabrication. It can create any shape or form that a customer desires to meet their production needs. Channel rolling allows for the creation of complex shapes and forms with precision, increasing efficiency while reducing cost. This process also ensures uniformity in material quality, resulting in smoother surfaces and tighter tolerances compared to conventional cutting methods. The strength and integrity of the steel remain intact after channel rolling, making it ideal for producing components required for structural applications such as construction beams and frames.

In addition, channel rolling can produce exact bends with minimal waste, which means lower costs for customers over time due to reduced scrap material generated from more traditional cutting processes. Ultimately, channel rolling makes steel fabrication easier by allowing designers to be creative without compromising on precision or quality standards.

How does Channel Rolling Work?

Channel rolling is a process used to create C-channels and U-channels from sheet metal. It involves feeding the material through a series of grooved rollers, which shape and form it into the desired channel shape. The rollers are computer controlled to ensure that they can produce uniform channels with precise dimensions. Not only does this provide an efficient way of creating these components, but it also ensures that they have consistent quality each time.

Channel rolling can be carried out on both ferrous and non-ferrous metals such as aluminum, copper, stainless steel, and carbon steel, allowing numerous industries to benefit from this manufacturing technique. Depending on the application, various methods can be used when applying pressure onto the material, including hydraulic power or manual operation by hand wheeling.

What Are Different Methods For Channel Rolling?

Channel rolling is a metalworking technique that creates custom shapes from metal sheets. It requires specialized machinery and offers superior accuracy and repeatability compared to traditional forming techniques such as bending. Different methods exist for channel rolling, including horizontal rollers, vertical rollers, rotary draw benders, presses, lathe machines, and laser cutters.

Horizontal roller channels are capable of producing more complex parts than vertical rollers due to the multiple axes available on them.

- Rotary draw benders are commonly used when creating large-diameter components with smooth contours. In contrast, press-forming can be used with certain metals that require higher rates of pressure to achieve the desired shape.

- Laser cutting is also an option for achieving intricate designs without requiring any additional material or setup time for each piece being formed.

All these methods offer unique advantages depending on the type of part being made and should be carefully considered before deciding which one will best suit your needs.

Harvey Brothers Inc.

- #1 Channel Rolling For Steel Fabrication in Cincinnati, Ohio

Harvey Brothers Inc.

is the number one channel rolling provider for steel fabrication in Cincinnati, Ohio. Our experienced staff of professionals uses state-of-the-art machinery and processes to provide superior results on all your steel fabrication needs. We specialize in custom shapes, sizes, bends, and lengths for any application and precision rolling of large channels up to 40 feet long. With a commitment to quality that has earned us an unsurpassed reputation in the industry, Harvey Brothers Inc.

is proud to be your go-to source for all your steel fabrication requirements!

FAQ's

What is channel rolling, and how is it different from pipe or tube rolling?

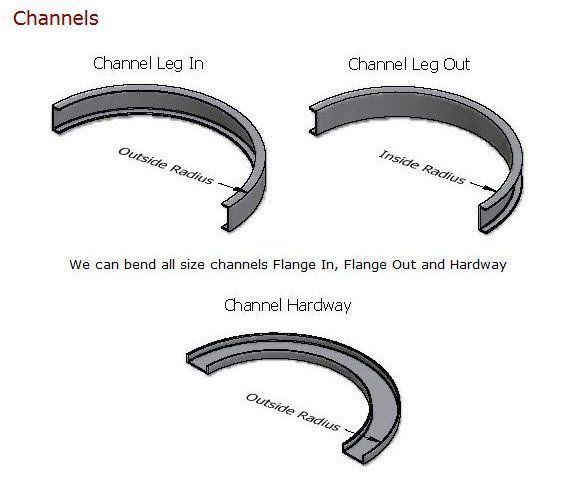

Channel rolling involves curving U-shaped structural steel, aluminum, or stainless channels into smooth arcs or complete circles while preserving their shape and dimensions. Unlike round pipes or tubes, channels have flat web and flange faces that can distort if not carefully managed. Harvey Brothers Inc. uses specialized rollers and techniques to maintain the integrity of both the web and flanges during bending. This service is ideal for architectural arches, structural frames, circular catwalks, and decorative applications requiring precise, consistent curves in channel stock.

What types of channel materials can you roll?

Harvey Brothers Inc. rolls a wide variety of materials including carbon steel, stainless steel, aluminum, and other specialty metals. Each material behaves differently during the rolling process based on its thickness, flange size, and mechanical properties. Our experienced team evaluates the type and grade of material to determine the ideal rolling approach, minimizing risks like flange separation, cracking, or bowing. Whether your project involves architectural aluminum channels or heavy-duty industrial steel, we tailor our methods for precise, high-quality results.

What industries commonly use rolled channels?

Rolled channels serve numerous industries, including construction, transportation, energy, shipbuilding, infrastructure, and public art installations. In Cincinnati, Harvey Brothers Inc. frequently provides rolled channels for arched roof supports, bridge railings, conveyor systems, curved architectural facades, catwalks, and industrial frameworks. These rolled components combine strength with aesthetic appeal, making them valuable in both structural and decorative applications. Our ability to deliver tight tolerances and clean, consistent curves makes us a trusted partner for a wide range of industrial and commercial projects.

What are the most common challenges when rolling channels?

The primary challenges in channel rolling involve controlling distortion of the flanges and web, maintaining the channel’s cross-sectional integrity, and preventing twisting or rippling. Channels naturally tend to deform during curving if not properly supported. Harvey Brothers Inc. uses specialized dies, precise rolling pressures, and multi-pass techniques to maintain dimensional accuracy. The direction of the curve (easy way, hard way, or off-axis) also impacts complexity. Our experienced Cincinnati operators analyze each job’s material and design to select the optimal rolling method.

What is the difference between “easy way” and “hard way” channel rolling?

“Easy way” rolling bends the channel along its web, allowing the flanges to open or close like arms, while “hard way” rolling bends against the web, forcing the flanges to compress or stretch — a much more difficult and distortion-prone operation. Hard way rolling requires advanced tooling and expertise to avoid twisting or flange deformation. Harvey Brothers Inc. has specialized equipment and proven processes for both rolling orientations, helping Cincinnati customers achieve desired results with minimal distortion.

What’s the typical turnaround time for a channel rolling order?

Turnaround times depend on the material, length, size, complexity, and shop scheduling. Standard single-piece or small-batch projects with in-stock materials can often be completed within 3–5 business days. Larger or more intricate orders requiring custom radii or tight tolerances may take 1–2 weeks. Harvey Brothers Inc. offers realistic, upfront lead time estimates when quoting your Cincinnati project. We also accommodate expedited services when possible for time-sensitive jobs and will communicate clearly to manage your expectations.

Can Harvey Brothers Inc. roll channels into full rings or spirals?

Yes — we regularly roll channels into complete rings, hoops, spirals, and partial arcs for industrial, commercial, and decorative applications. Spiral rolling is particularly useful for stair stringers, conveyors, and sculptural elements. The process requires careful control of both curve radius and pitch (rise per turn). Harvey Brothers Inc. uses precision-calibrated machines and skilled operators to produce high-quality, uniform spirals and rings with reliable dimensional accuracy, ensuring clean weld joints or seamless connections for assembly.

What are the hidden benefits of choosing rolled channels over fabricated bends?

Rolled channels offer several advantages over cut-and-welded fabricated bends, including increased strength, smoother curves, and better visual continuity. Avoiding welded joints reduces weak points and potential failure areas in structural applications. Rolled components also require less labor, reducing fabrication time and costs. Harvey Brothers Inc. ensures consistent radii, minimizing alignment issues during assembly. For architects and designers, rolled channels deliver uninterrupted curves that enhance aesthetics and project value while providing a structurally sound solution.

Do you offer rolling for customer-supplied materials?

Yes — Harvey Brothers Inc. can roll both customer-supplied and in-house sourced materials. If you already have specific channel stock purchased for your project, simply supply it along with your specifications. We inspect all incoming materials to confirm they meet the necessary criteria for rolling, ensuring optimal results and minimizing waste. If you prefer, we can also source high-quality materials through our trusted suppliers in Cincinnati, simplifying your project logistics.

How do you ensure consistent quality and accuracy when rolling channels?

We achieve accuracy through precise machine calibration, controlled multi-pass rolling, and in-process dimensional checks. Channels are measured throughout the rolling process to ensure the radii and curve alignment match your specifications. Harvey Brothers Inc. uses skilled operators and specialized tooling tailored to different material types and rolling directions. For projects requiring certified tolerances, we can provide dimensional inspection reports upon request. Consistent quality control at every stage guarantees that our rolled channels meet or exceed expectations.