Choosing the Right Metal for Your Rolling Project

Rolling projects, whether construction, manufacturing, or arts and crafts, require a keen eye for detail, especially when selecting the right metal. The outcome of your project largely depends on the choice of metal. Here's a guide to help you make an informed decision.

1. Determine Your Project's Requirements

Begin with a clear understanding of what you need:

- Durability: Do you need a metal that can handle rough treatment, or is the project more for show? For instance, outdoor structures need strong metals that resist wear and tear.

- Weight: If your project has weight restrictions, like in aviation or transport, you'll need to consider lighter metals.

- Budget: It's great to want the best, but sometimes you'll need to find a middle ground between quality and what you can afford.

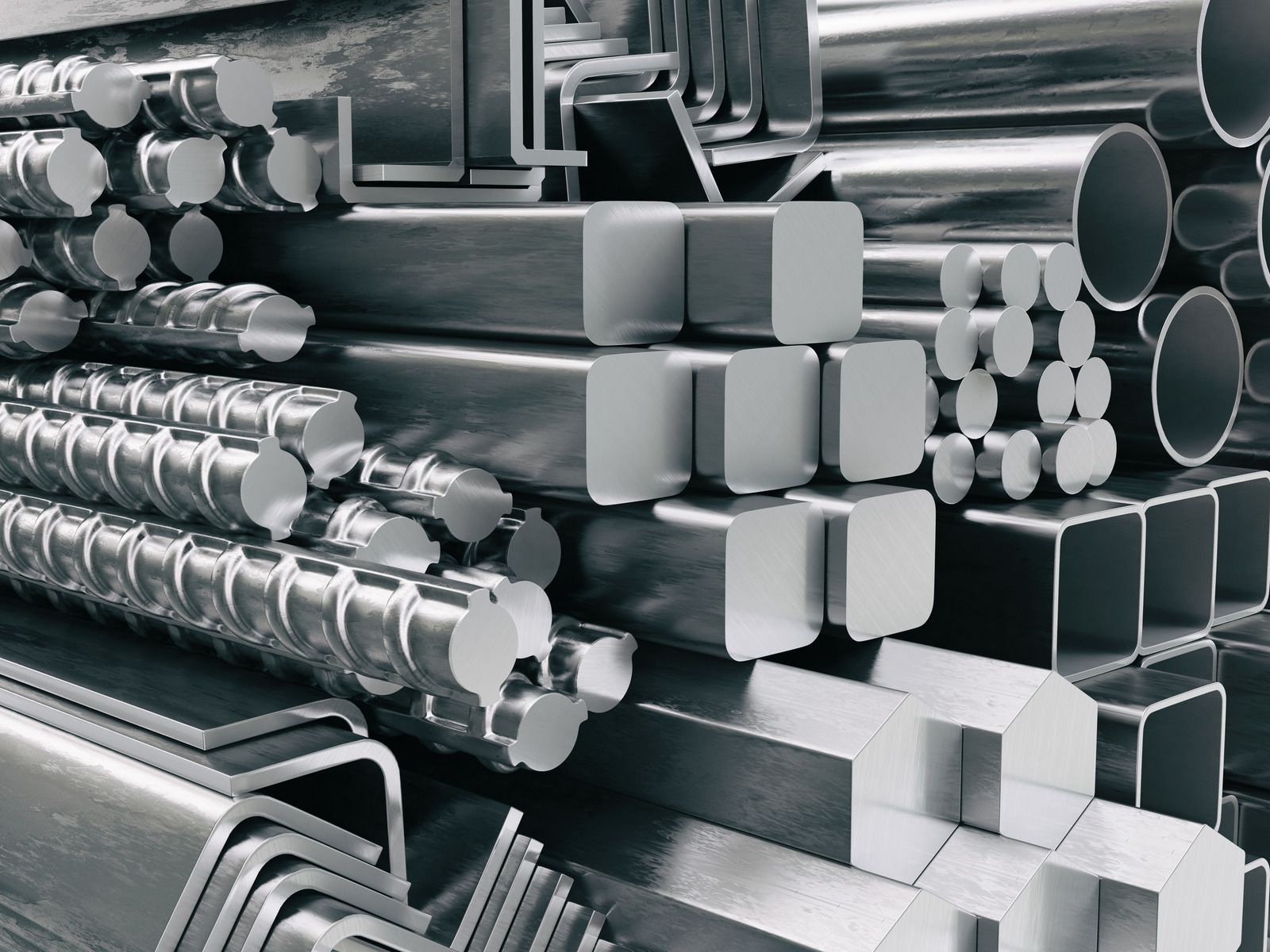

2. Get to Know the Basics of Common Metals

Knowing a bit about the most common metals can be helpful:

- Steel: Durable and strong, steel is commonly used in construction. It's also cost-effective, which is great for larger projects.

- Aluminum: It's light and doesn't rust easily. That's why aluminum is popular for things like window frames and even airplanes.

- Copper: It's more than just a pretty metal. Copper conducts electricity very well, so it's handy for electrical tasks.

- Brass: This is a mix of copper and zinc. Brass resists rust and has a shiny, golden color, making it a favorite for decorative items.

- Stainless Steel: Imagine the strength of steel but without the rust. That's stainless steel for you. It's often used in kitchens and hospitals because it's clean and durable.

3. Think About Surface Treatments

Sometimes, a metal might need a little extra protection or a different look:

- Galvanizing: This process coats steel or iron with zinc to protect it from rusting.

- Anodizing: This treatment, mainly used for aluminum, protects against wear and corrosion.

- Plating: By adding a layer of another metal like copper or nickel, you can change the appearance or properties of your metal.

4. Consider How You'll Work with the Metal

Every metal behaves differently:

- Malleability: If you need to shape the metal by hammering or rolling, check how easily it can be molded.

- Weldability: If you'll be joining pieces together, it's essential the metal welds well without losing strength.

5. Account for the Environment

Where your project ends up matters:

- Corrosive Environments: If the metal will be around chemicals or saltwater, you need something that won't corrode easily.

- Temperature Changes: Some metals handle heat or cold better than others. Make sure your metal choice will remain stable.

6. Ask the Experts

There's no harm in getting a second opinion:

- Talk to Suppliers: They deal with metals daily and can offer insights based on the latest trends and technologies.

- Join Online Groups: Online forums and community groups can be a treasure trove of real-world advice from people who've been there and done that.

Picking the right metal isn't just about looks or price. It's about understanding your project and finding a metal that matches those needs. By doing your research and seeking out advice when needed, you can feel confident in your choice, ensuring your project isn't just successful but also built to last.