Importance of Bar Rolling Services

When it comes to manufacturing bars, the rolling process plays a critical role in ensuring that they meet industry standards for quality, size, and strength. Bar rolling services are an essential part of the process and can significantly affect the finished product's overall quality. In this article, we'll explore the importance of bar rolling services, how they work, and why they're necessary for producing high-quality bars.

The Basics of Bar Rolling Services

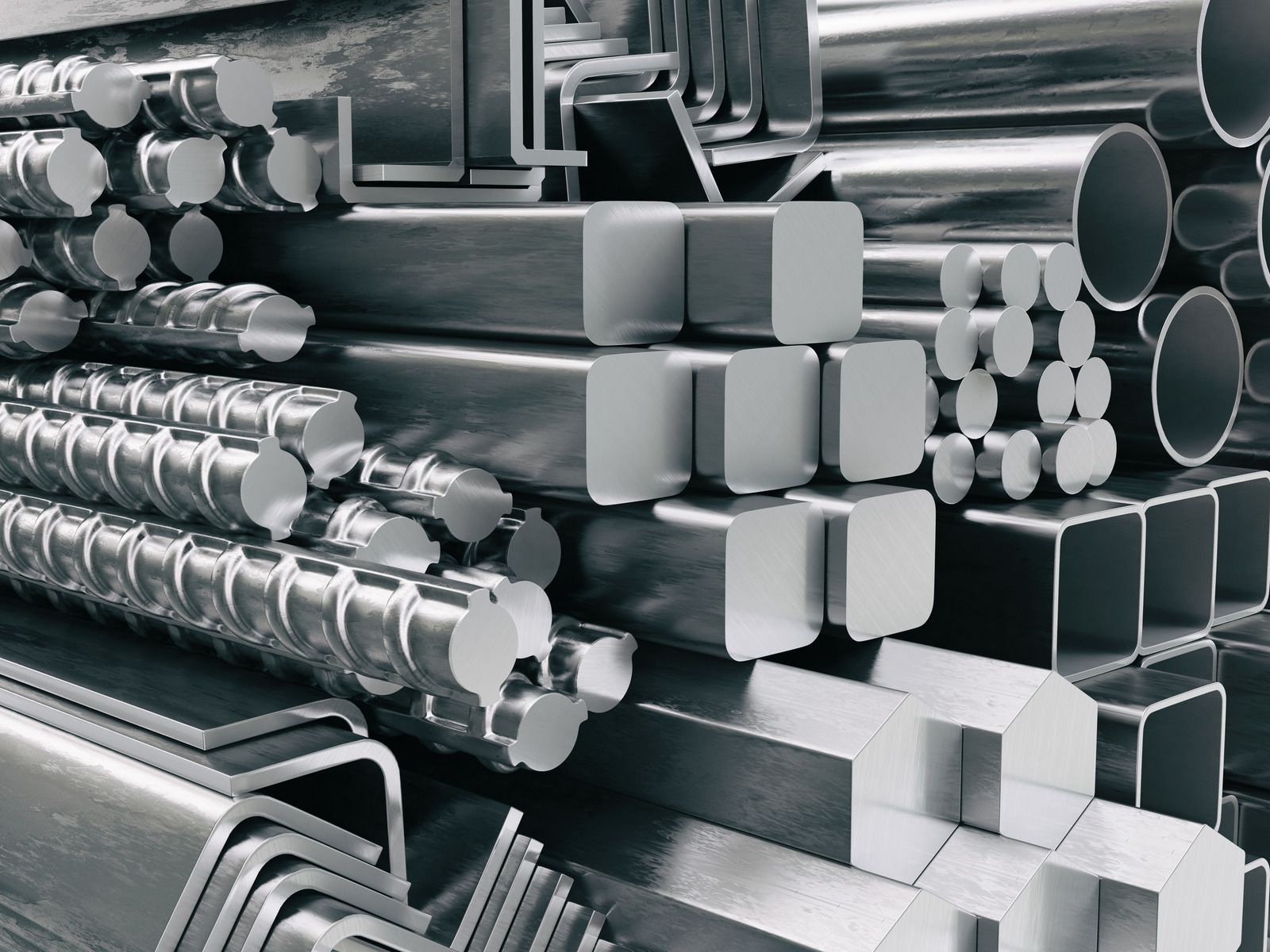

Bar rolling services are a specialized form of metalworking that involves rolling long, cylindrical bars of metal through a series of rollers to reduce their diameter and increase their length. The process involves applying pressure to the metal, which causes it to deform and elongate. This results in a stronger, more durable bar that can be used in various industrial applications.

The Advantages of Bar Rolling Services

There are many advantages to using bar rolling services in the manufacturing process. One of the most significant benefits is that it allows for precise control over the final product's dimensions, making it easier to produce bars that meet industry standards. Additionally, bar rolling services can help improve the quality of the finished product by reducing the risk of defects and flaws that can compromise its integrity.

The Different Types of Bar Rolling Services

Several different types of bar rolling services are available, each with unique advantages and disadvantages. Two of the most common types are hot rolling and cold rolling. Hot rolling involves heating the metal to high temperatures before rolling it, while cold rolling is done at room temperature. Other types of bar rolling services include ring rolling and rotary piercing.

Why You Should Invest in Bar Rolling Services

If you're involved in the manufacturing of bars or other metal products, investing in bar rolling services can be an excellent way to improve the quality and consistency of your products. By working with a reputable provider of bar rolling services, you can ensure that your bars meet industry standards for size, strength, and quality. This can help you attract new customers and improve your reputation within the industry.

Finding the Right Bar Rolling Service Provider

When it comes to bar rolling services, it's essential to work with a provider that has experience, expertise, and a reputation for quality. Look for a company that has a proven track record of delivering high-quality products and that uses the latest technology and techniques to ensure that your bars meet your specifications. Additionally, make sure that the provider you choose offers excellent customer service and support, so you can get the help you need when you need it.

Conclusion

In summary,

bar rolling services are an essential part of the metalworking industry, and they offer many benefits to manufacturers and consumers alike. By investing in bar rolling services, you can improve your bars' quality, consistency, and durability, making them more attractive to customers and helping to build your reputation within the industry. With the right provider, you can be confident that your bars will meet industry standards and exceed your expectations for quality and performance.