How Precision Plate Rolling Transforms Flat Steel Into Curved Architectural Masterpieces?

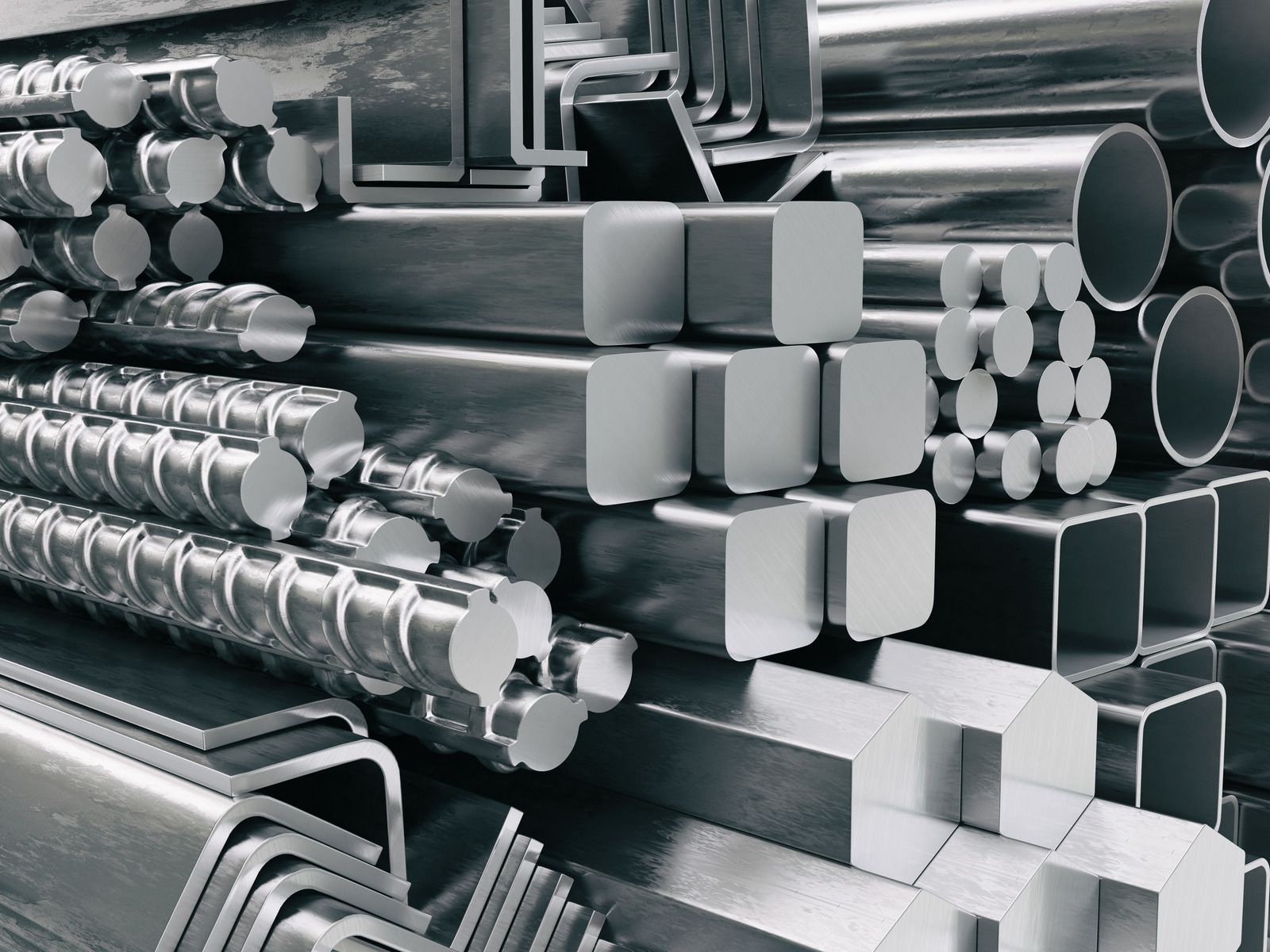

Precision plate rolling is a cornerstone of modern metal fabrication, enabling flat steel plates to take on smooth, continuous curves that meet both functional and aesthetic demands. This process is essential for industries ranging from construction and manufacturing to energy and transportation, where high-quality curved steel components are required. By bending steel without compromising its strength, precision plate rolling ensures structural integrity while delivering visually striking results.

What Is Precision Plate Rolling?

Precision plate rolling is a metal forming technique that converts flat steel plates into cylindrical, conical, or curved shapes. Using a series of rollers, the steel is gradually bent to achieve the desired curvature while preserving its uniform thickness and mechanical properties. Unlike welding or cutting methods, which join or remove material, plate rolling reshapes the steel continuously, producing smooth, flawless curves.

This method accommodates various plate sizes and thicknesses, allowing for custom radii and specific geometric requirements. The result is a high-strength, visually seamless component ideal for architectural facades, industrial tanks, structural supports, and other curved metal applications.

How the Process Works

The precision plate rolling process begins with selecting the appropriate steel plate and roller configuration. The plate is fed through three or more rollers arranged in a triangular or pyramid formation. As the plate passes through, each roller incrementally bends the steel until the target radius or curve is achieved. Operators can adjust roller pressure and alignment to produce both tight curves and broad arcs depending on project specifications.

Temperature management also plays a critical role. While some steel grades bend easily at room temperature, others may require controlled heating to reduce internal stress and prevent cracks. Skilled monitoring throughout ensures that the rolled plate maintains its strength, durability, and surface quality.

Key Benefits of Precision Plate Rolling

One of the main advantages of precision plate rolling is accuracy. The process allows for consistently precise curves across multiple plates, reducing errors and rework. It also minimizes material waste, as steel is reshaped rather than cut or welded, making it a cost-effective solution for large-scale projects.

Another key benefit is versatility. Precision plate rolling can accommodate various metals including mild steel, stainless steel, and aluminum, as well as a wide range of thicknesses and plate sizes. This flexibility allows engineers and designers to use curved plates for both structural and decorative purposes, combining strength with visual appeal.

Common Applications

Precision plate rolling is widely used across industries. In construction, it produces curved beams, arches, and facade elements that create striking architectural designs. In industrial applications, rolled plates form tanks, silos, pressure vessels, and piping systems that require perfect cylindrical or conical shapes. Transportation industries use rolled steel in ship hulls, railcars, and aircraft components, where durability and curvature are critical. Even decorative and public art projects leverage plate rolling to achieve sweeping curves and elegant forms.

Why It Matters

Precision plate rolling is more than just bending steel—it is a technique that combines engineering accuracy, structural reliability, and design creativity. Understanding this process allows architects, fabricators, and project managers to plan effectively, ensuring that both functional and aesthetic goals are met.

Conclusion

Harvey Brothers Inc., based in Cincinnati, Ohio, offers

professional precision plate rolling services that turn flat steel into curved architectural masterpieces. With a commitment to quality, precision, and efficiency, they provide solutions that meet the diverse needs of industries requiring dependable and visually stunning curved steel components.