Importance of Bar Rolling in Steel Fabrication Process

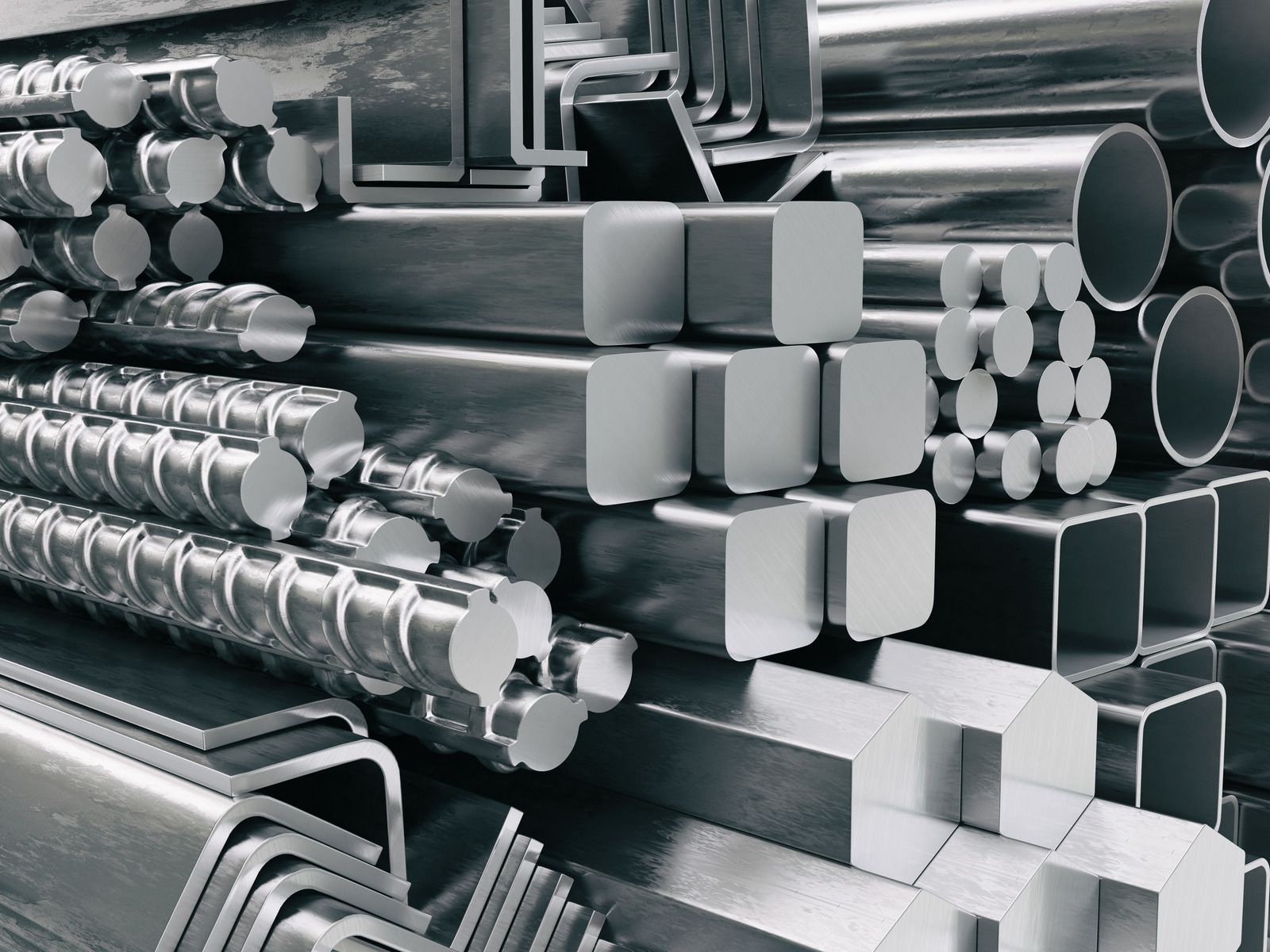

Bar rolling is a critical process in steel fabrication that involves shaping metal bars into various forms and sizes. This technique is vital in producing a wide range of products used in multiple industries, including construction, automotive, manufacturing, and infrastructure development. This blog will explore the importance of bar rolling in the steel fabrication process, highlighting its benefits and applications.

Definition of Bar Rolling

Bar rolling, also known as rod rolling, is a metal forming process that involves passing metal bars through sets of specially designed rollers to reduce their cross-sectional area and shape them into desired profiles. This process is commonly used to create round, square, hexagonal, or custom-shaped bars.

Production of Standardized Shapes

Bar rolling is essential for producing standardized shapes of steel bars, which are widely used in construction projects and various industries. These standardized shapes include round bars, square bars, and flat bars, which are crucial components in manufacturing structures, machinery, and tools.

Enhanced Strength and Uniformity

The steel bars undergo a controlled deformation process through bar rolling, enhancing their strength and uniformity. This results in improved mechanical properties, such as increased tensile strength and reduced variations in cross-sectional dimensions, making the bars more reliable and predictable for critical applications.

Versatility in Steel Fabrication

Bar rolling offers versatility in steel fabrication, allowing manufacturers to create a wide range of products with different shapes, sizes, and specifications. The process can be adapted to meet the specific requirements of diverse industries, making it a fundamental technique in steel processing.

Cost-Effectiveness

Bar rolling is a cost-effective method in steel fabrication as it enables the production of large quantities of standardized shapes in a relatively short time. The efficient process helps reduce production costs and meet the demands of various construction and manufacturing projects.

Precise Tolerance Control

Bar rolling involves a series of carefully calibrated rollers that ensure precise tolerance control during the shaping process. This enables manufacturers to produce steel bars with consistent dimensions, meeting the strict quality standards required in various applications.

Reduction in Material Waste

By utilizing bar rolling, manufacturers can significantly reduce material waste. The process allows for the efficient use of raw materials, ensuring minimal leftover scrap and optimizing the overall yield.

Contribution to Sustainable Practices

As bar rolling reduces material waste and enhances material utilization, it contributes to sustainable practices in steel fabrication. This aligns with the global drive towards eco-friendly and resource-efficient manufacturing processes.

Customization for Specific Applications

Bar rolling offers the flexibility to create custom-designed steel bars for specific applications. Manufacturers can tailor the process to produce bars with unique profiles, dimensions, and properties, catering to the diverse needs of different industries.

Impact on Infrastructure Development

The importance of bar rolling extends beyond industrial applications, as it significantly impacts infrastructure development. Steel bars produced through this process are vital in constructing bridges, buildings, highways, and other infrastructure projects.

Conclusion

Bar rolling is a crucial process in steel fabrication, significantly shaping metal bars into standardized and custom-designed profiles. The versatility, efficiency, and cost-effectiveness of bar rolling make it an essential technique in various industries, including construction, manufacturing, and infrastructure development. The process ensures the production of reliable and high-quality steel bars for a wide range of applications through precise tolerance control and enhanced mechanical properties. As sustainable practices gain momentum in manufacturing, bar rolling's contribution to material efficiency and reduced waste further underscores its importance in steel fabrication.