Built to Last: The Advantages of High-Quality Bar Rolling

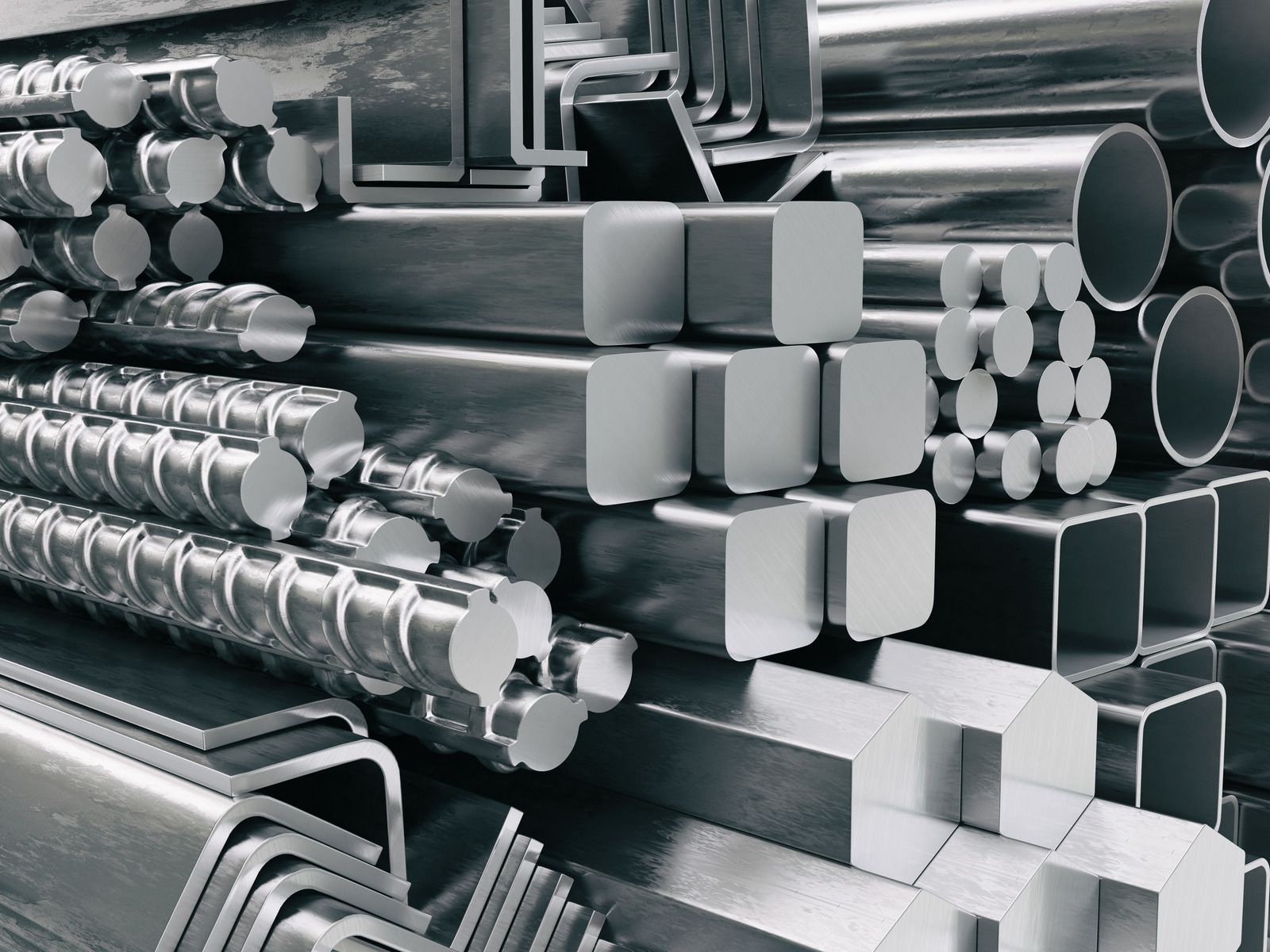

The quality of the materials used in construction plays a major role in ensuring strong and durable constructions. Steel bars are a necessary part of many construction projects.

Bar rolling is a process used to enhance these bars' overall quality, strength, and durability. The advantages of premium bar rolling and the reasons it's important to make sure structures are built to last will be covered in this article.

Advantages Of High-Quality Bar Rolling

Enhanced Strength And Durability

By exposing steel bars to high pressure and heat, superior bar rolling creates a denser and more consistent grain arrangement. This procedure significantly increases the bars' strength and endurance, making them more appropriate for supporting heavy loads and withstanding a range of environmental conditions. Superior rolling bar construction reduces the likelihood of bending, warping, or failing even under extreme conditions.

Improved Structural Integrity

Improved product integrity is one of the major benefits of premium bar rolling. Rolled steel has high structural stability and reliability as it prevents defects and irregularities including voids, cracks and uneven grain distribution. This reduces the chances of failure of the structure and ensures the safety of its assets and protects from damage.

Uniformity And Consistency

A major benefit of using high-quality bar rolling is achieving uniformity and consistency in the finished product. Producers can achieve consistent bar dimensions, mechanical properties, and surface quality by accurately regulating the rolling process parameters, such as temperature, pressure, and speed. By ensuring uniformity, construction projects may seamlessly incorporate bars into their designs and minimize the risk of installation-related issues. Each bar will meet all applicable regulations, standards, and specifications.

Cost-Effectiveness

Even while it could cost more up front than more traditional ways, high-quality bar rolling is a more affordable choice. Over the course of a structure's life, roller bars require less maintenance and repair since they are more resilient, long-lasting, and durable. Building project expenses are further reduced since the enhanced performance of these bars reduces the need for expensive structural modifications or reinforcements.

Environmental Sustainability

Superior bar rolling reduces waste production and maximizes material use to support environmental sustainability. Manufacturers can reduce waste and offcuts while increasing raw material yield by carefully controlling the rolling process. Additionally, rolled bars' strength and longevity prolong the service life of structures, lowering the need for frequent replacements and ultimately saving resources. Builders can lessen the environmental effects of their projects and support sustainable construction practices by selecting premium rolled bars.

Compliance with Standards and Regulations

Superior bar rolling guarantees adherence to industry guidelines and rules controlling the manufacturing and application of building supplies. Manufacturers follow stringent quality control protocols and testing processes to ensure that rolled bars fulfill or surpass the requirements for strength, dimensional accuracy, and performance. By adhering to standards, rolling bar buildings are guaranteed to be safe, dependable, and compliant with relevant codes and guidelines by regulators, builders, and developers.

Quality Bar Rolling For Durable Projects

Building durable structures requires a number of advantages that come with high-quality bar rolling. Rolled bars have benefits like enhanced strength and durability, better structural integrity, and environmental sustainability, making them crucial for guaranteeing the longevity and performance of building projects. By using premium rolled bars, builders can meet the strictest quality and compliance requirements while creating more cost-effective, durable, and safe structures.