8 Remarkable Examples Of Channel Rolling In Everyday Structures

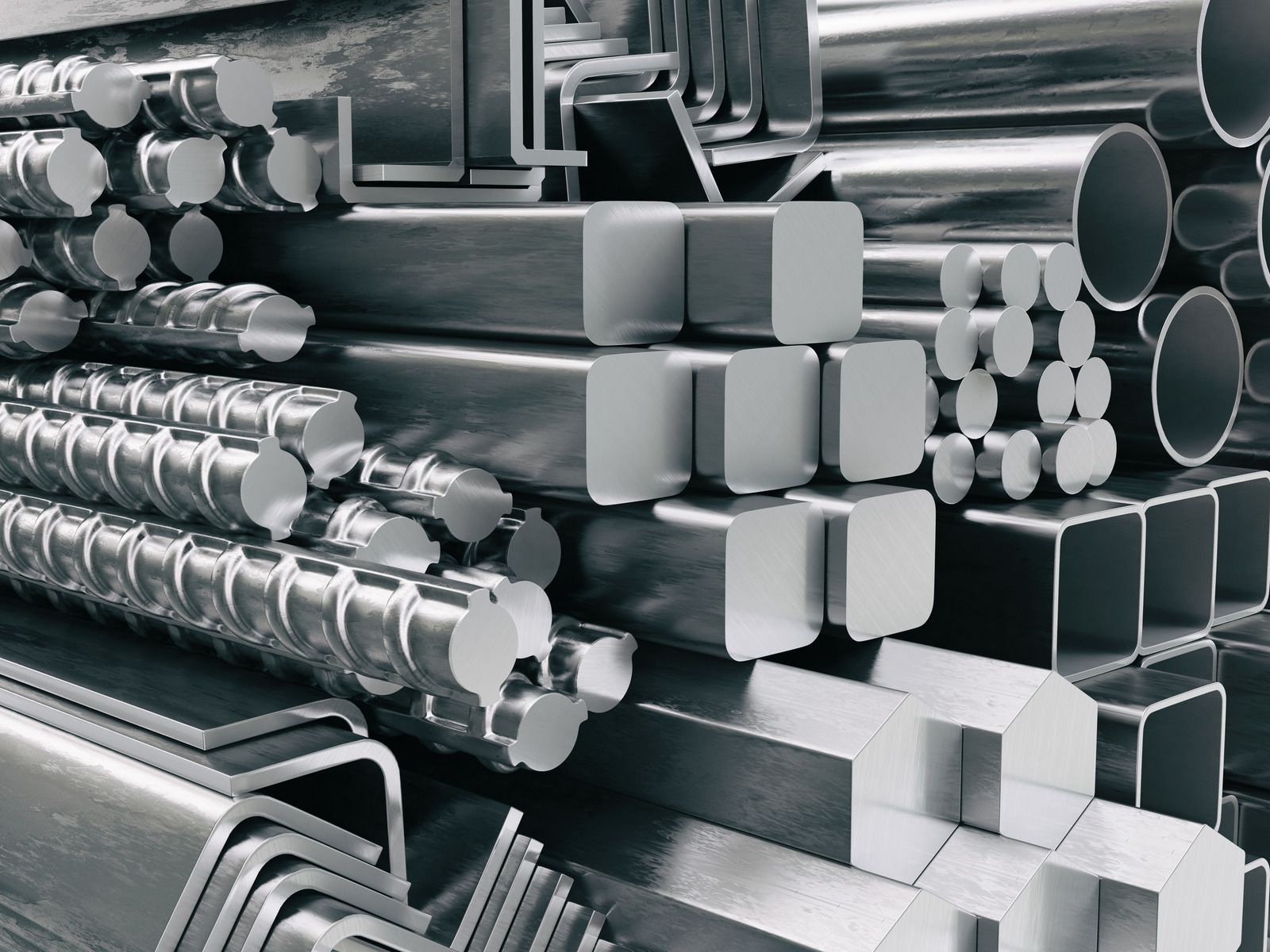

Channel rolling shapes steel into strong, curved channels that support structures both large and small. These channels may not always stand out, yet they hold great importance in modern construction and design. From public infrastructure to industrial sites, channel rolling ensures durability, safety, and functionality. The process allows flat steel to form curved supports that carry heavy loads and resist stress with ease.

Understanding where rolled channels appear in daily life reveals how deeply they contribute to the world around us. With every project, channel rolling demonstrates its flexibility, making it a trusted method across many industries.

1. Bridges

Bridges rely on rolled channels to maintain strength while spanning long distances. Curved channels distribute weight evenly, which prevents strain on one section. Their presence ensures both safety and longevity.

2. Stadium Roofs

Large stadiums need lightweight yet powerful supports. Channel rolling creates curved beams that form the framework of wide-span roofs. These beams allow open spaces without bulky columns blocking views.

3. Industrial Warehouses

Rolled channels form arches and supports in warehouse facilities. By reducing material waste while maximizing strength, they keep storage areas safe and efficient. The curved channels hold roofing structures securely under heavy loads.

4. Transportation Tunnels

Tunnels use rolled channels as reinforcements along curved walls. These shapes match the natural form of tunnels, ensuring both stability and resistance against soil pressure. Their strength keeps transport systems safe for daily use.

5. Airport Hangars

Hangars that store aircraft need wide, clear spaces. Channel rolling produces the curved steel sections that allow long spans without internal pillars. This design makes movement of planes smooth and unrestricted.

6. Water Treatment Plants

Many treatment plants use large tanks and curved channels to support them. Rolled channels fit perfectly around circular tanks, strengthening their frames. This structural support helps plants operate safely and continuously.

7. Shopping Malls

Modern malls often feature wide atriums with open ceilings. Rolled channels help create these open areas by forming curved sections that hold glass or roofing materials in place. Their design supports both beauty and function.

8. Agricultural Buildings

Barns and greenhouses often need curved roofs that withstand heavy weather. Rolled channels make these shapes possible. Their strength ensures that farming structures remain durable while meeting daily needs.

Why Channel Rolling Matters

Each example shows how channel rolling connects engineering with everyday use. The technique reduces material costs, adds durability, and allows creative designs that balance strength with efficiency. Its role stretches from essential infrastructure to spaces where people gather, work, or live.

The adaptability of channel rolling also helps builders explore designs that were once difficult or costly, opening doors to stronger, safer, and more innovative projects. With its proven reliability, channel rolling has secured its place as one of the most important processes in modern construction.

Conclusion

Harvey Brothers Inc., located in Cincinnati, Ohio, offers

professional channel rolling services that provide strong, accurate, and cost-effective solutions for industries and builders who rely on curved steel for lasting structures.