5 Ways Precision Bar Rolling Enhances Industrial Efficiency

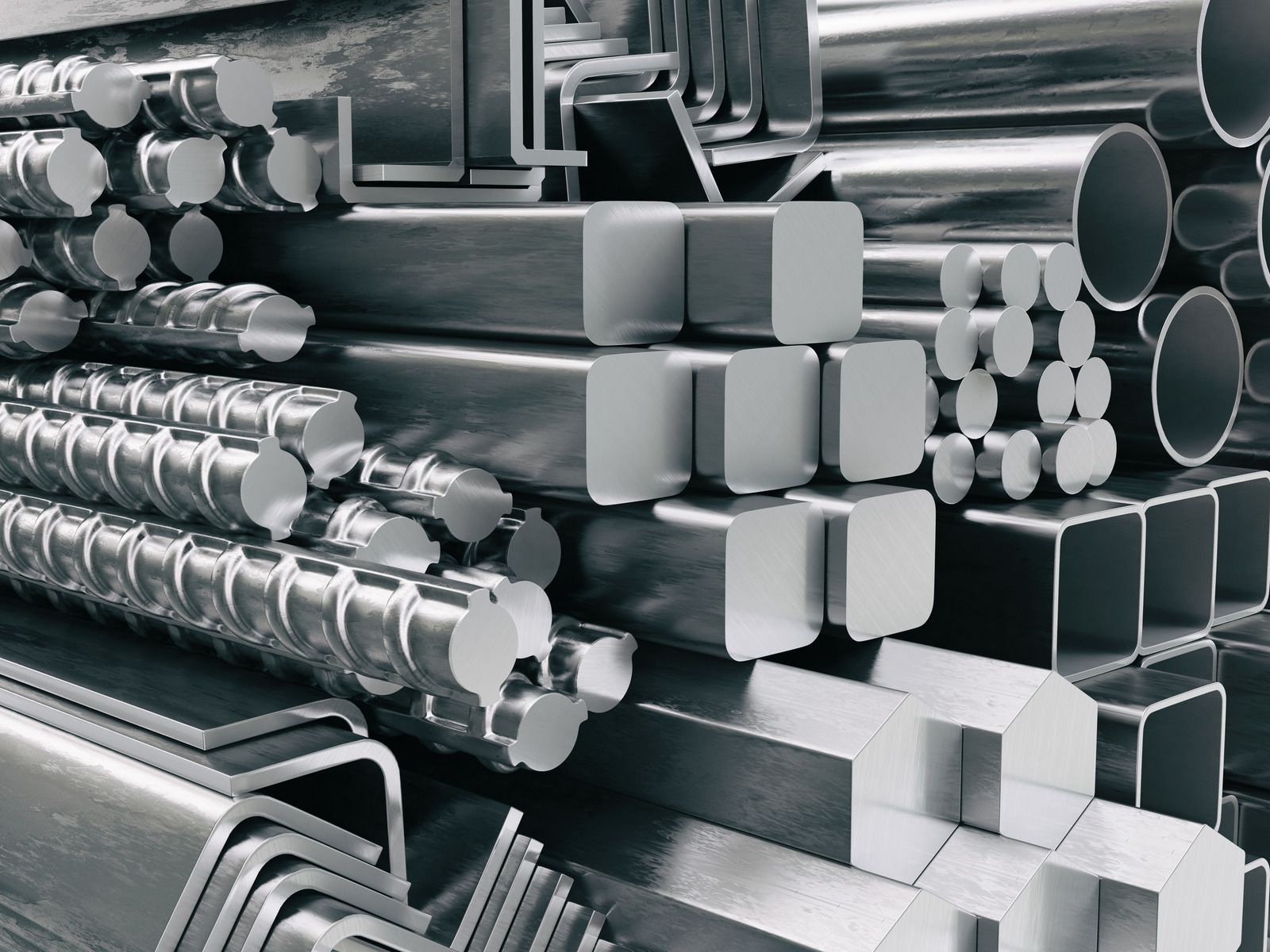

Precision bar rolling offers a vital method for shaping metal bars to precise measurements. This approach supports industries requiring high-quality materials designed to meet specific standards. Fields like construction, automotive, and manufacturing depend on these materials for reliable and efficient performance.

The process delivers accuracy, enhances performance, and reduces operational costs. Many businesses consider precision bar rolling an essential technique for producing consistent and durable materials. Below, discover the 5 ways this method provides for various industrial uses.

1. Enhanced Accuracy

Achieving exact dimensions allows industries to meet stringent standards. By producing materials with precise measurements, waste diminishes significantly during production. Components crafted through this method integrate seamlessly into industrial systems. Efficient assembly reduces time and labor, increasing overall productivity. Businesses that demand exact specifications find this process invaluable for maintaining quality in their operations.

2. Improved Strength and Durability

Precision bar rolling aligns the internal structure of metals, improving their resilience under stress. This structural alignment enhances longevity, making materials ideal for demanding environments. Parts created through this method perform consistently even under heavy loads. Stronger and more durable components lead to fewer replacements, ensuring uninterrupted operations. By prioritizing strength, this process supports reliable functionality across industrial applications.

3. Cost-Effective Production

Reduced material waste directly lowers production expenses. The process minimizes errors, helping industries avoid costly interruptions during manufacturing. Companies can efficiently produce large volumes of high-quality materials at lower costs. Businesses save resources without compromising the integrity of their products. This method proves essential for industries seeking sustainable and affordable solutions.

4. Versatility Across Applications

This technique accommodates various metals, including alloys, to meet diverse industrial demands. Bars produced using this method can vary in size and shape, offering flexibility for different projects. Construction and automotive sectors often utilize this process for creating customized components. Versatility ensures compatibility with unique project requirements, simplifying industrial production. By supporting multiple industries, precision bar rolling adapts to countless manufacturing needs.

5. Reliable Consistency

Uniformity remains critical in ensuring product reliability. This technique produces batches with consistent quality, reducing variations that might disrupt industrial operations. Materials created through precision bar rolling integrate seamlessly into systems, improving their overall performance. Businesses gain confidence in their materials, knowing they meet every specification. Maintaining consistency reduces risks associated with equipment failure, making it essential for critical applications.

Additional Advantages of Precision Bar Rolling

Beyond accuracy and strength, precision bar rolling improves surface finishes. Smoother materials reduce friction, enhancing performance in mechanical systems. Faster production cycles meet tight deadlines while maintaining high standards. Industries gain valuable benefits without sacrificing quality or efficiency.

Eco-friendly practices contribute to this method’s appeal. By reducing waste, the process supports environmental goals. Many companies value its ability to align with sustainability efforts. Recyclable materials used during production further enhance its environmentally conscious approach.

Precision bar rolling revolutionizes industrial production through its many advantages. Accuracy, strength, versatility, and cost savings make it an essential tool for countless industries. Smooth finishes and consistent results support reliable performance across various applications. By incorporating sustainable practices, the method benefits businesses while reducing environmental impact. Precision bar rolling remains a trusted solution for achieving optimal results in manufacturing.